Liquid Source Vaporization Control Systems - Principle of Vaporization

Injection method

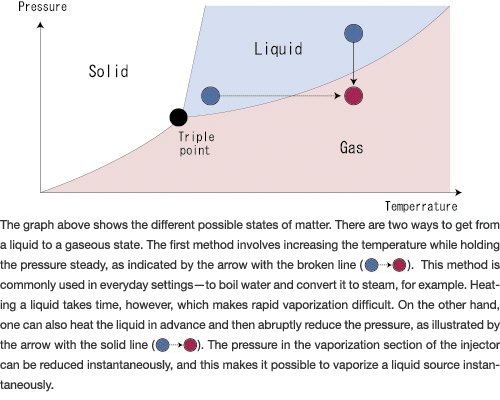

The following list covers the major steps involved in vaporizing a liquid source and supplying it to the process chamber.

1. The liquid source's flow rate is measured and the amount of liquid is feedback controlled by the valve.

2. The liquid is instantaneously and completely vaporized.

3. The gas is released without being allowed to condense back into its liquid form.

Vaporization systems that use the injection method sequentially carry out steps 1, 2, and 3 listed above. The VC series units measure the liquid flow of the liquid source using a mass flow meter and do not use a carrier gas. The MI/MV series units use a mass flow meter for measurement and feature a mass flow controller that introduces a carrier gas into the unit to vaporize the liquid source.

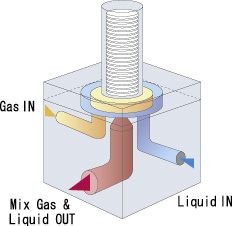

Gas and liquid mixture method

This is the vaporization method used in the MI/MV series. Since the pressure on the carrier gas is higher at the front of the nozzle inside the injector, it can be heated efficiently. The liquid source and the heated carrier gas are mixed together in the gas/liquid mixing area in the front of the nozzle, and the pressure is reduced as they pass through the nozzle, vaporizing the mixture. Vaporization efficiency is higher than with traditional vaporization methods. When this method is used, larger flows can be generated, and the generation temperature can be reduced.